The Tower Handbook

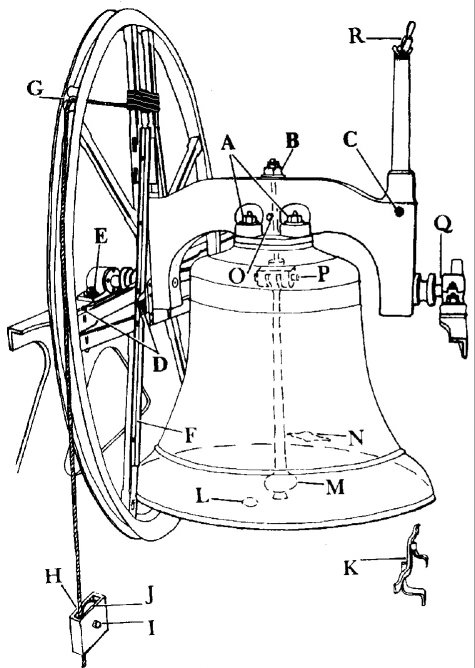

Metal headstocks are reasonably maintenance-free, but check all nuts for tightness once or twice a year. Keep nuts and protruding ends of bolts rust-free. Watch out for signs of rusty dust (oxide) around nuts and gudgeon fixings. This could mean that something is loose. See section 14.7c for information on twiddle pins.

Bell with one type of metal headstock

A = Bell retaining bolts

B = Crown staple nut

C = Bolt securing stay

D = Bolts securing the two parts of the wheel

E = Bolt securing bearing to frame

F = Steel angle wheel stay

G = Garter hole

H = Ground pulley box

I = Ground pulley grease cap

J = Ground pulley

K = Hastings stay slider bar

L = Normal clapper wear on soundbow

M = Ball of clapper

N = Groove on soundbow caused by loose clapper

O = Twiddle pins for centring clapper bolt

P = Clapper bearing grease cap

Q = Grease seal on main bearing

R = Hastings stay toggle or dingle

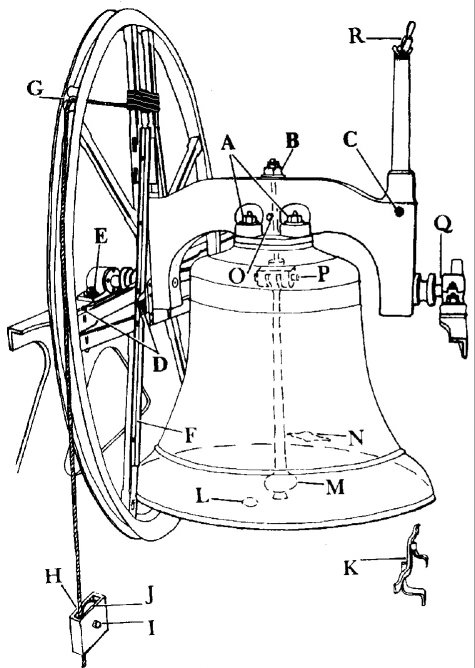

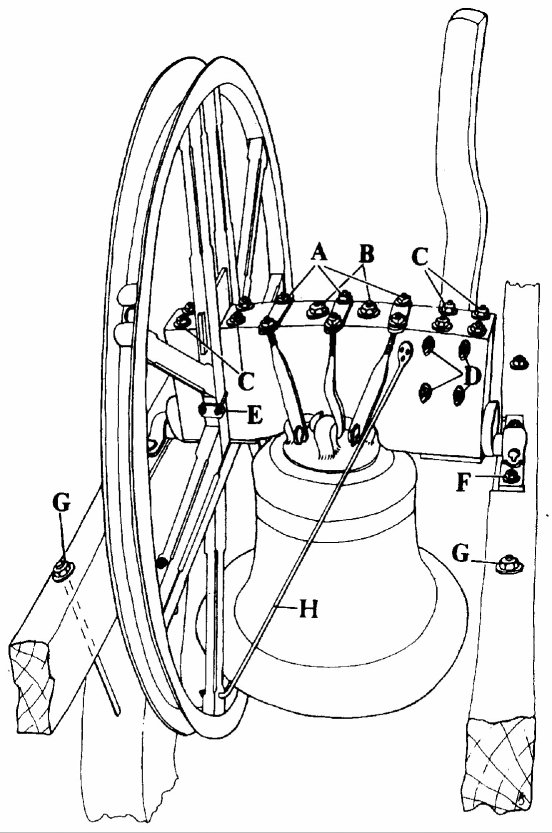

Timber headstocks may have up to a dozen bolts through them, all with nuts which need to be kept tight. The timber tends to expand and contract with the weather so these nuts ought to be checked two or three times a year, but especially during long dry spells. A typical installation may have four nuts at each end of the headstock securing the gudgeon plates, four or more nearer the centre securing the bell itself, and one or two at the centre to fix the clapper. Attend to each of these groups separately. Start with the gudgeon nuts at both ends, then move on to the nuts on the stays or bolts holding the bell, tightening each group diagonally [221]. Finally tighten the nut(s) securing the clapper itself. For general information on nuts and bolts see section 14.12a.

Bell with timber headstock

Bell with timber headstock

A = Straps holding bell to headstock

B = Nuts securing argent U-bolts

C = Nuts securing gudgeon U-bolts

D = Nuts securing bolts or U-bolts holding the stay

E = Bolts securing wheel to headstock

F = Bolts securing bearing to frame

G = Frame tie rods

H = Wheel-stay or brace (may be wood on older installations)

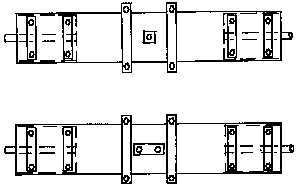

Typical timber headstocks

Typical timber headstocks

A = Headstock with independent clapper staple (one central bolt)

B = Headstock with cast-in staple. The two central nuts are on the U-bolts holding the argent.

Currently hosted on jaharrison.me.uk